Products

Well-Designed Stainless Steel Wire Rope PVC Coated - Compacted Steel Wire Rope for mine hoisting – Elevator

Well-Designed Stainless Steel Wire Rope PVC Coated - Compacted Steel Wire Rope for mine hoisting – Elevator Detail:

Product Description

As outer strands of the rope go through crimping wheels, the strand becomes thicker – metal cross sectional area increases, strand form becomes smoother, and round, therefore the following advantages are achieved:

*increased wear resistance of wires

*decreased blocks groove wearing

*high tensile strength

*higher lateral compression strength

Organic fillers inside the rope serve as additional lubrication source which enables to protect the core from corrosion and reduce friction between rope core and outer strands.

Polymer material between the metal core and the outer strands protects the core from corrosion and decreases wire wear caused by strand friction on the core.

These advantages extend the operational life of the rope and significantly reduce operating costs.

Application

LIFT, CRANE, MINE CABLEWAY

Advantage of surface contact ropes

1. Stronger to abrasion.

2. Disconnection does not occur easily.

3. Stronger to corrosion- Corrosion from the outside is small between wires are in close contact with each other.

4. Breaking load is larger than the weight.

5. Easy handling and extend the life of DrumSibu.

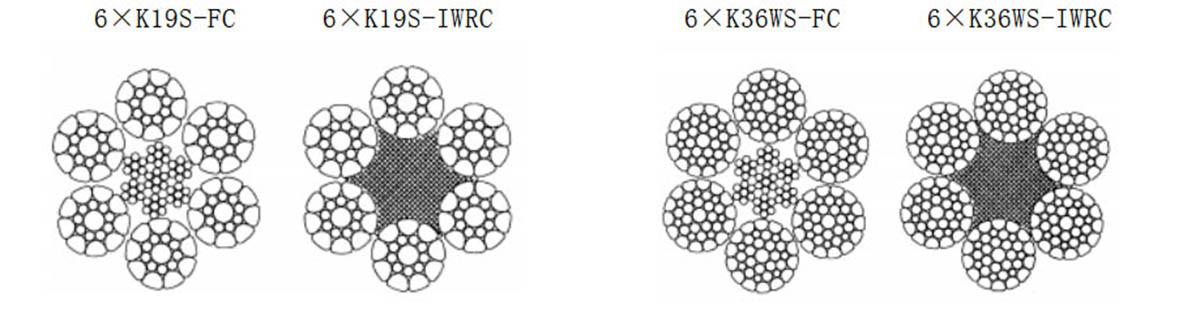

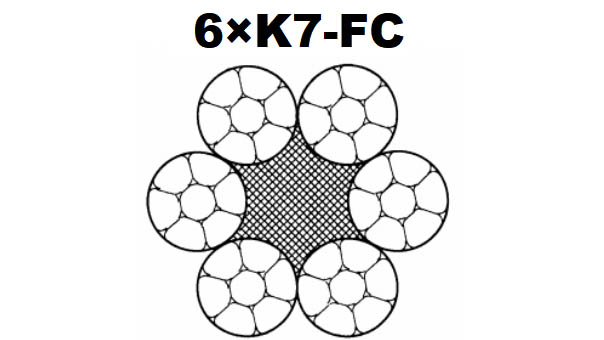

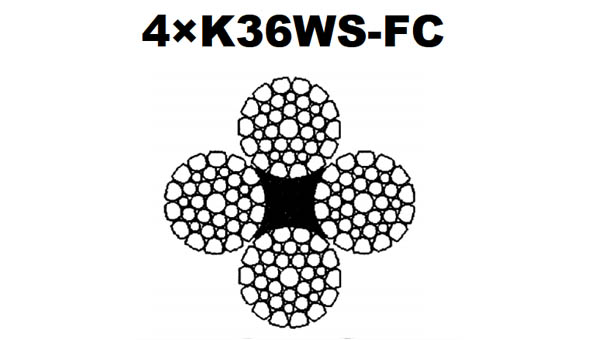

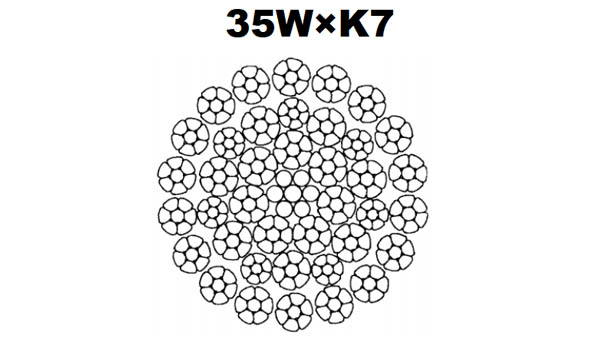

Construction

35W×K7, 4×K36WS-FC, 6×K7-FC, 6×K19S&6×K36WS

Construction

|

Nominal Diameter |

Approximate Weight |

Minimum Breaking Load Corresponding To Rope Grade Of |

||||||||

|

Fiber Core |

Steel Core |

1570 |

1770 |

1960 |

2160 |

|||||

|

FC |

SC |

FC |

SC |

FC |

SC |

FC |

SC |

FC |

SC |

|

|

MM |

KG/100M |

KN |

KN |

KN |

KN |

KN |

KN |

KN |

KN |

KN |

|

10 |

42.5 |

46.5 |

58.6 |

65.2 |

66 |

73.5 |

73.1 |

81.3 |

80.6 |

89.6 |

|

12 |

61.2 |

67 |

84.3 |

93.8 |

95.1 |

106 |

105 |

117 |

116 |

129 |

|

14 |

83.3 |

91.1 |

115 |

128 |

129 |

144 |

143 |

159 |

158 |

176 |

|

16 |

109 |

119 |

150 |

167 |

169 |

188 |

187 |

208 |

206 |

230 |

|

18 |

138 |

151 |

190 |

211 |

214 |

238 |

237 |

264 |

261 |

290 |

|

20 |

170 |

186 |

234 |

261 |

264 |

294 |

292 |

325 |

322 |

359 |

|

22 |

206 |

225 |

283 |

315 |

320 |

356 |

354 |

394 |

390 |

434 |

|

24 |

245 |

268 |

337 |

375 |

380 |

423 |

421 |

469 |

464 |

516 |

|

26 |

287 |

314 |

396 |

440 |

446 |

497 |

494 |

550 |

545 |

606 |

|

28 |

333 |

365 |

459 |

511 |

518 |

576 |

573 |

638 |

632 |

703 |

|

30 |

382 |

419 |

527 |

586 |

594 |

661 |

658 |

732 |

725 |

807 |

|

32 |

435 |

476 |

600 |

667 |

676 |

752 |

749 |

833 |

825 |

918 |

|

34 |

491 |

538 |

677 |

753 |

763 |

849 |

845 |

940 |

931 |

1040 |

|

36 |

551 |

603 |

759 |

844 |

856 |

952 |

947 |

1050 |

1040 |

1160 |

|

38 |

614 |

671 |

846 |

941 |

953 |

1060 |

1060 |

1170 |

1160 |

1290 |

|

40 |

680 |

744 |

937 |

1040 |

1060 |

1180 |

1170 |

1300 |

1290 |

1430 |

|

42 |

750 |

820 |

1030 |

1150 |

1160 |

1300 |

1290 |

1430 |

1420 |

1580 |

|

44 |

823 |

900 |

1130 |

1260 |

1280 |

1420 |

1420 |

1570 |

1560 |

1740 |

|

46 |

899 |

984 |

1240 |

1380 |

1400 |

1550 |

1550 |

1720 |

1700 |

1900 |

|

48 |

979 |

1070 |

1350 |

1500 |

1520 |

1690 |

1680 |

1870 |

1830 |

2070 |

|

50 |

1060 |

1160 |

1460 |

1630 |

1650 |

1840 |

1830 |

2030 |

2010 |

2240 |

|

52 |

1150 |

1260 |

1580 |

1760 |

1790 |

1990 |

1980 |

2200 |

2180 |

2420 |

Construction

|

Nominal Diameter |

Approximate Weight |

Mini.Breaking Load Corresponding To Rope Grade Of |

||

|

1570 |

1770 |

1960 |

||

|

MM |

KG/100M |

KN |

KN |

KN |

|

10 |

41 |

58.9 |

66.4 |

73.5 |

|

12 |

59 |

84.8 |

95.6 |

106 |

|

14 |

80.4 |

115 |

130 |

144 |

|

16 |

105 |

151 |

170 |

188 |

|

18 |

133 |

191 |

215 |

238 |

|

20 |

164 |

236 |

266 |

294 |

|

22 |

198 |

285 |

321 |

356 |

|

24 |

236 |

339 |

382 |

423 |

|

26 |

277 |

398 |

449 |

497 |

|

28 |

321 |

462 |

520 |

576 |

|

30 |

369 |

530 |

597 |

- |

|

32 |

420 |

603 |

680 |

- |

|

34 |

474 |

681 |

767 |

- |

|

36 |

531 |

763 |

860 |

- |

|

38 |

592 |

850 |

958 |

- |

|

40 |

656 |

942 |

1060 |

- |

Construction

|

Nominal Diameter |

Approximate Weight |

Mini.Breaking Load Corresponding To Rope Grade Of |

|||

|

1570 |

1770 |

1960 |

2160 |

||

|

MM |

KG/100M |

KN |

KN |

KN |

KN |

|

22 |

218 |

312 |

351 |

389 |

429 |

|

24 |

259 |

371 |

418 |

463 |

510 |

|

26 |

304 |

435 |

491 |

543 |

599 |

|

28 |

353 |

505 |

569 |

630 |

694 |

|

30 |

405 |

579 |

653 |

723 |

797 |

|

32 |

461 |

659 |

743 |

823 |

907 |

|

34 |

520 |

744 |

839 |

929 |

1020 |

|

36 |

583 |

834 |

941 |

1040 |

1150 |

|

38 |

650 |

930 |

1050 |

1160 |

- |

|

40 |

720 |

1030 |

1160 |

1290 |

- |

|

42 |

794 |

1140 |

1280 |

1420 |

- |

|

44 |

871 |

1250 |

1400 |

1560 |

- |

|

46 |

952 |

1360 |

1540 |

1700 |

- |

|

48 |

1040 |

1480 |

1670 |

1850 |

- |

Construction

|

Nominal Diameter |

Approximate Weight |

Mini.Breaking Load Corresponding To Rope Grade Of |

|||

|

1570 |

1770 |

1960 |

2160 |

||

|

MM |

KG/100M |

KN |

KN |

KN |

KN |

|

12 |

73.4 |

93.8 |

106 |

117 |

129 |

|

14 |

100 |

128 |

144 |

159 |

176 |

|

16 |

131 |

167 |

188 |

208 |

230 |

|

18 |

165 |

211 |

238 |

264 |

290 |

|

20 |

204 |

261 |

294 |

325 |

359 |

|

22 |

247 |

315 |

356 |

394 |

434 |

|

24 |

294 |

375 |

423 |

469 |

516 |

|

26 |

345 |

440 |

497 |

550 |

606 |

|

28 |

400 |

511 |

576 |

638 |

703 |

|

30 |

459 |

586 |

661 |

732 |

807 |

|

32 |

522 |

667 |

752 |

833 |

918 |

|

34 |

590 |

753 |

849 |

940 |

1040 |

|

36 |

661 |

844 |

952 |

1050 |

1160 |

|

38 |

736 |

941 |

1060 |

1170 |

1290 |

|

40 |

816 |

1040 |

1180 |

1300 |

1430 |

|

42 |

900 |

1150 |

1300 |

1430 |

1580 |

|

44 |

987 |

1260 |

1420 |

1570 |

1740 |

|

46 |

1080 |

1380 |

1550 |

1720 |

1900 |

|

48 |

1180 |

1500 |

1690 |

1870 |

2070 |

|

50 |

1280 |

1630 |

1840 |

2030 |

2240 |

|

52 |

1380 |

1760 |

1990 |

2200 |

- |

|

54 |

1490 |

1900 |

2140 |

2370 |

- |

|

56 |

1600 |

2040 |

2300 |

- |

- |

|

58 |

1720 |

2190 |

2470 |

- |

- |

|

60 |

1840 |

2350 |

2640 |

- |

- |

Product detail pictures:

Related Product Guide:

We attempt for excellence, provider the customers", hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Well-Designed Stainless Steel Wire Rope PVC Coated - Compacted Steel Wire Rope for mine hoisting – Elevator , The product will supply to all over the world, such as: Johor, Wellington, Namibia, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.