Traction ropes

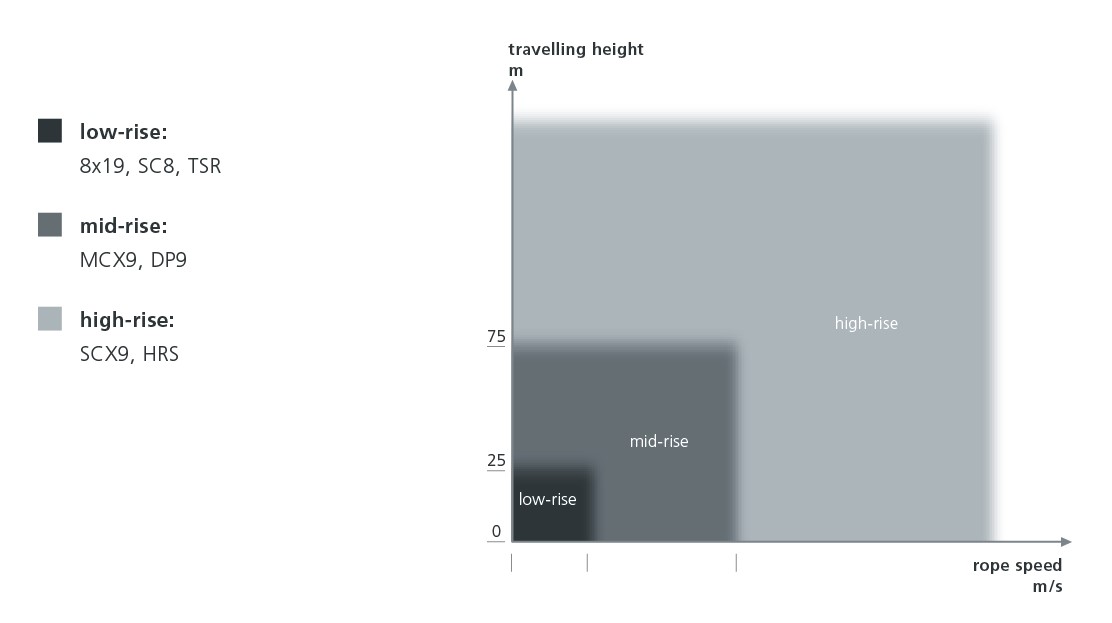

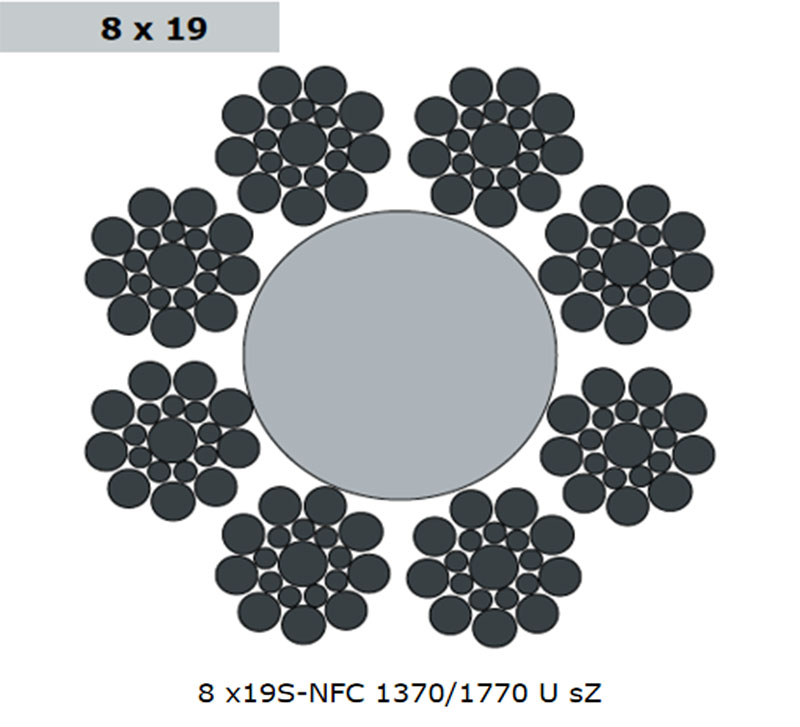

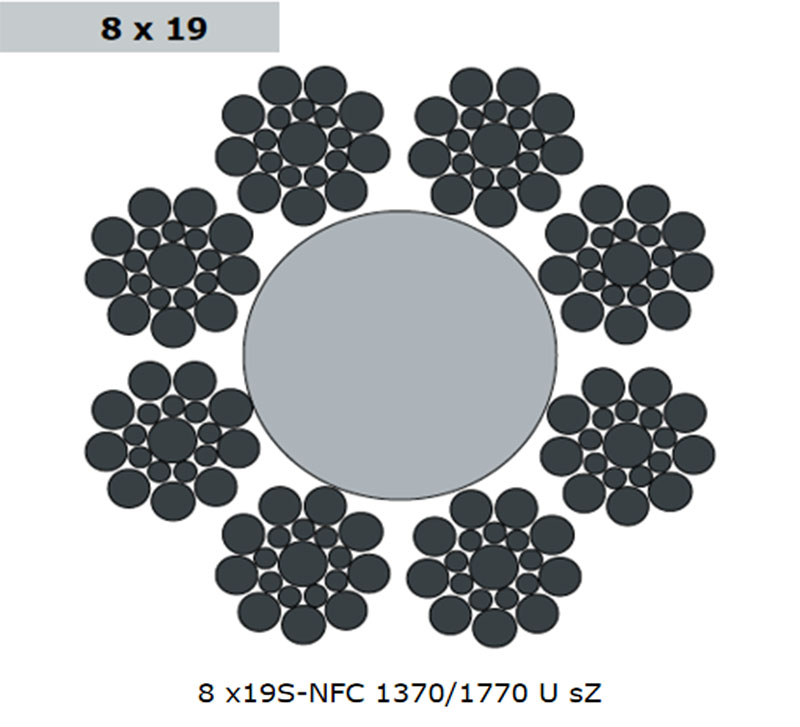

8*19

This rope type is the traction sheave rope world-wide most frequently used for the low and lower mid-rise area.

good fatigue properties, good elongation values, round rope diameter, all groove types

frequency up to ≈ 200.000 trips / year rope speed ≈ 5,0 m / s, travelling height up to 75 m

Rope data

• 8 strands, regular lay right-hand

• seale-construction, 19 wires / strand • nominal tensile grade 1370 / 1770 N / mm2

• bright, basic-lubricated

• impregnated sisal fiber core

• white i-LINE for installation check

• e-Modul: 110,000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,122 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,26 % of traction rope length

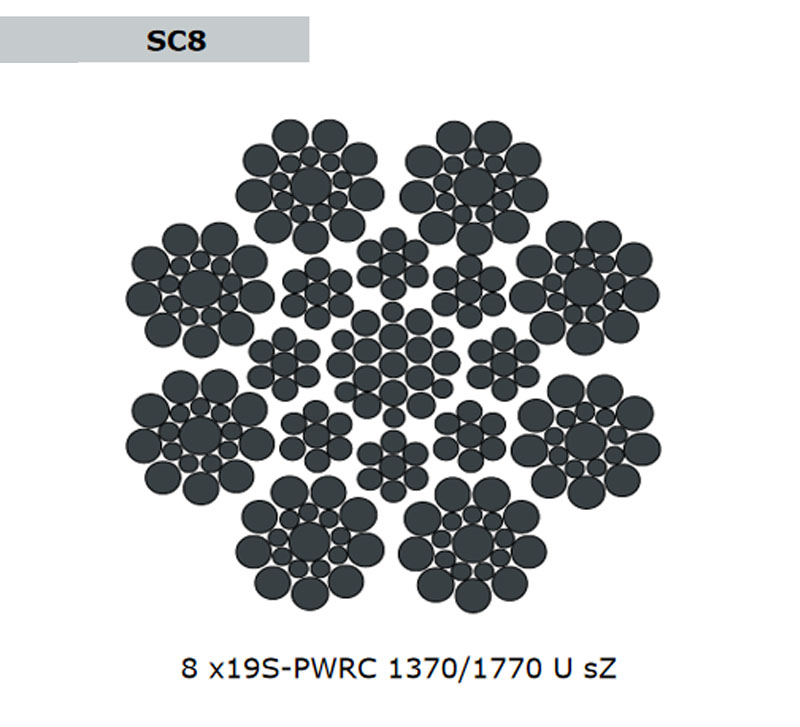

sc8

For traction sheave, freight and hydraulic elevators in the low- and mid-rise area.

very good fatigue properties, high breaking load, very good elongation values, round rope diameter, all groove types

frequency up to ≈ 250.000 trips / year, rope speed up to ≈ 5,0 m / s, travelling height up to 75 m, standard rope guides

Rope data

• 8 strands, regular lay right-hand

• seale-construction, 19 wires / strand

• nominal tensile grade 1370/1770 N / mm2

• bright, basic-lubricated

• steel core

• green i-LINE for installation check

• e-modul: 120.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,108 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,13 % of traction rope length

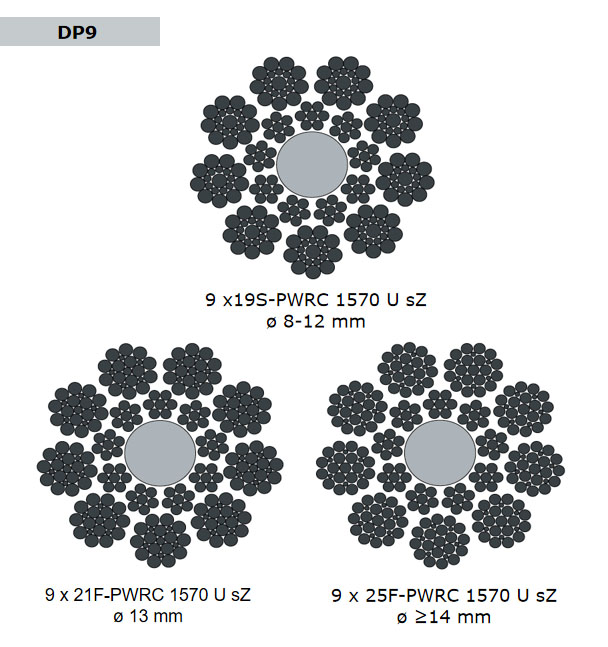

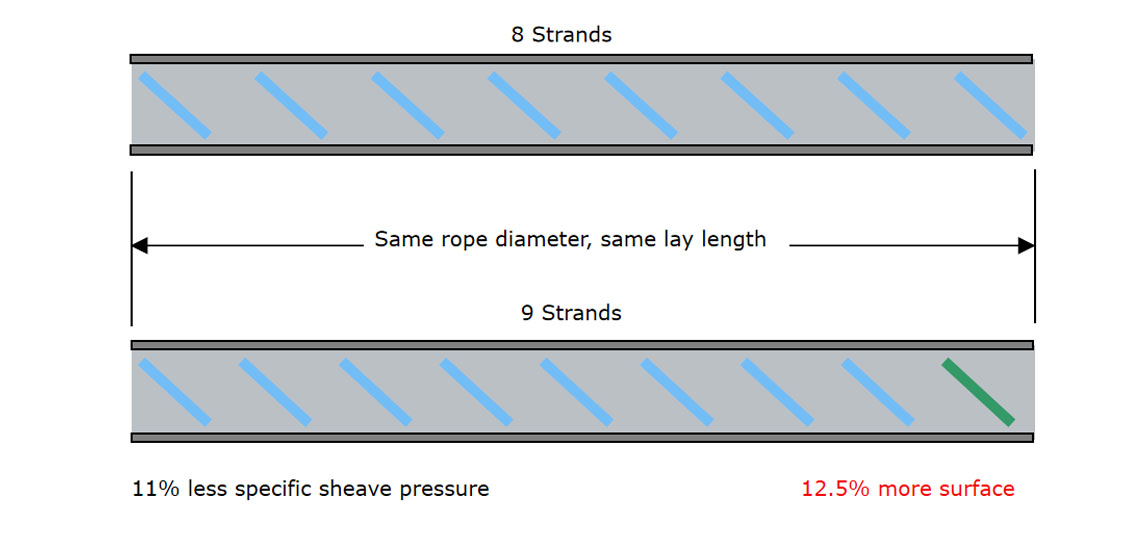

DP9

For traction sheave elevators in the mid-rise area.

• very good fatigue properties, medium breaking load, good elongation values, very round adaptive rope diameter

• high frequency from ≈ 350.000 trips / year, rope speed up to ≈ 5 m / s, travelling height up to ≈ 120 m

Rope data

• 9 strands, regular lay right-hand

• seale- and filler-constructions, according to nominal rope diameter 19, 21 or 25 wires / strand

• nominal tensile grade 1570 N / mm2

• bright, basic-lubricated

• polypropylene-fiber core, preformed and postformed

• yellow i-LINE for installation check

• e-modul: 115.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,112 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,25 % of traction rope length

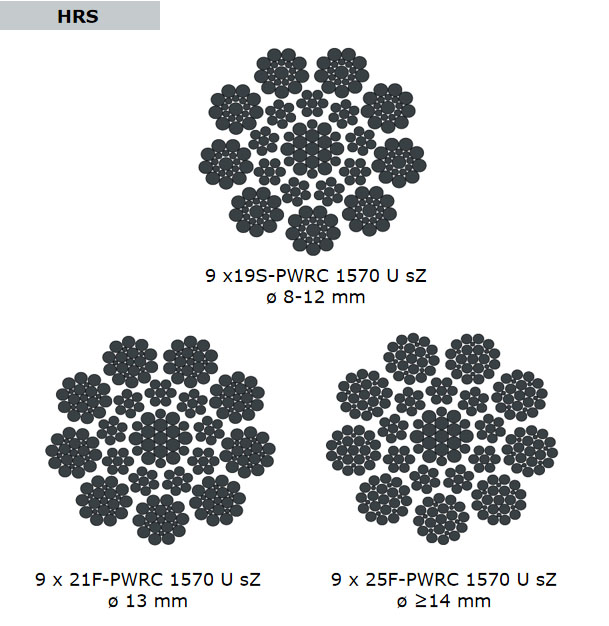

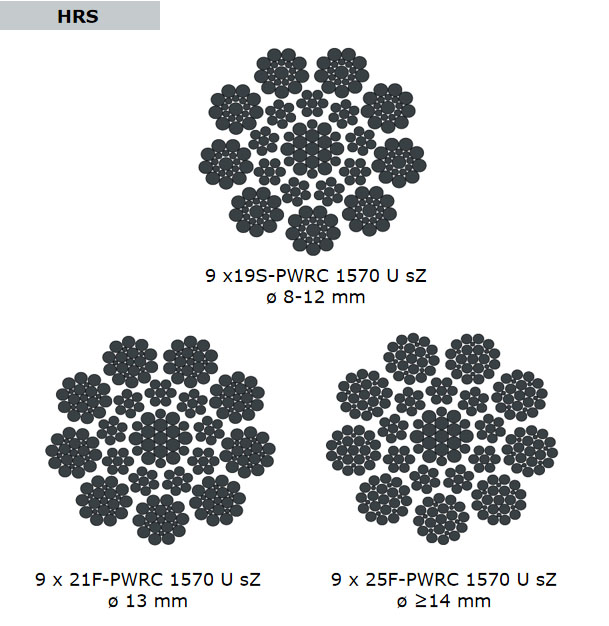

HRS

For traction sheave elevators in the high-rise area.

• excellent fatigue properties, very high breaking load, excellent elongation values, very round sturdy rope diameter

• high frequency from ≈ 200.000 trips / year, rope speed up to ≈ 12 m / s, travelling height more than ≈ 90 m

Rope data

• 9 strands, regular lay right-hand • seale-filler constructions

• according to nominal rope diameter - ø 19, 21 or 25 wires / strands

• nominal tensile grade 1570 N / mm2

• bright, basic-lubricated

• steel core

• blue i-LINE for installation check

• e-modul: 125.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,104 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,13 % of traction rope length

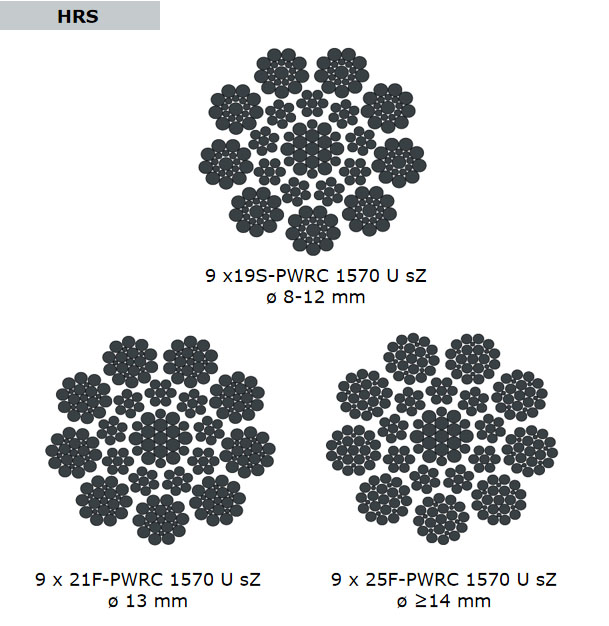

HRS

For traction sheave elevators in the high-rise area.

• excellent fatigue properties, very high breaking load, excellent elongation values, very round sturdy rope diameter

• high frequency from ≈ 200.000 trips / year, rope speed up to ≈ 12 m / s, travelling height more than ≈ 90 m

Rope data

• 9 strands, regular lay right-hand • seale-filler constructions

• according to nominal rope diameter - ø 19, 21 or 25 wires / strands

• nominal tensile grade 1570 N / mm2

• bright, basic-lubricated

• steel core

• blue i-LINE for installation check

• e-modul: 125.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,104 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,13 % of traction rope length

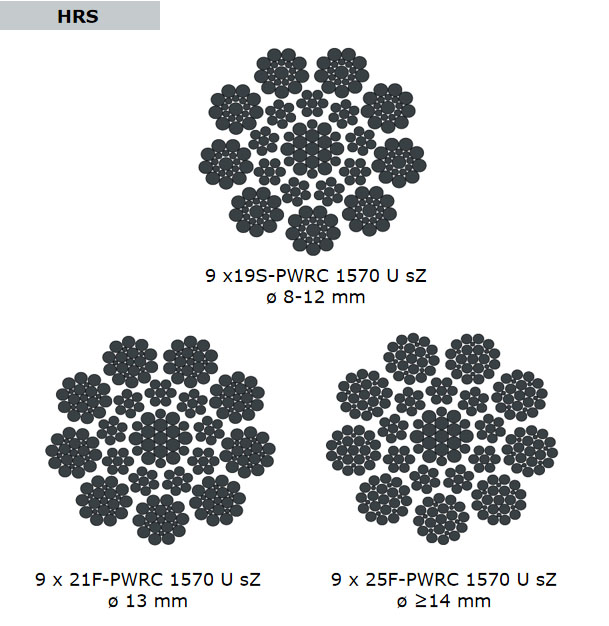

HRS

For traction sheave elevators in the high-rise area.

• excellent fatigue properties, very high breaking load, excellent elongation values, very round sturdy rope diameter

• high frequency from ≈ 200.000 trips / year, rope speed up to ≈ 12 m / s, travelling height more than ≈ 90 m

Rope data

• 9 strands, regular lay right-hand • seale-filler constructions

• according to nominal rope diameter - ø 19, 21 or 25 wires / strands

• nominal tensile grade 1570 N / mm2

• bright, basic-lubricated

• steel core

• blue i-LINE for installation check

• e-modul: 125.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,104 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,13 % of traction rope length

HRS

For traction sheave elevators in the high-rise area.

• excellent fatigue properties, very high breaking load, excellent elongation values, very round sturdy rope diameter

• high frequency from ≈ 200.000 trips / year, rope speed up to ≈ 12 m / s, travelling height more than ≈ 90 m

Rope data

• 9 strands, regular lay right-hand • seale-filler constructions

• according to nominal rope diameter - ø 19, 21 or 25 wires / strands

• nominal tensile grade 1570 N / mm2

• bright, basic-lubricated

• steel core

• blue i-LINE for installation check

• e-modul: 125.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,104 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,13 % of traction rope length

Governor ropes

6*19

The governor rope most frequently used word-wide. high breaking load, very good elongation values, zinc coated, metered lubrication, PP core

Rope data

• 6 strands, regular lay right-hand

• seale-construction,19 wires / strand

• nominal tensile grade 1960 N / mm2

• zinc coated, basic-lubricated

• polypropylene-fiber core

• no i-LINE • e-modul: 105.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,084 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,22 % of traction rope length

8*19

Governor rope for the mid- and high-rise area with special demand on the smooth performance. good elongation values, round rope diameter, zinc coated, metered lubrication, PP core

Rope data

• 8 strands, regular lay right-hand

• seale-construction, 19 wires / strand

• nominal tensile grade 1770 N / mm2

• zinc coated, basic-lubricated

• polypropylene core

• no i-LINE • e-modul: 110.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,142 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,22 % of traction rope length

8*19

Governor rope for the mid- and high-rise area with special demand on the smooth performance. good elongation values, round rope diameter, zinc coated, metered lubrication, PP core

Rope data

• 8 strands, regular lay right-hand

• seale-construction, 19 wires / strand

• nominal tensile grade 1770 N / mm2

• zinc coated, basic-lubricated

• polypropylene core

• no i-LINE • e-modul: 110.000 N / mm2

• elastic elongation at 10 % of the minimal breaking load is approx. 0,142 % of traction rope length

• remaining elongation (DIN 51201) is approx. 0,22 % of traction rope length

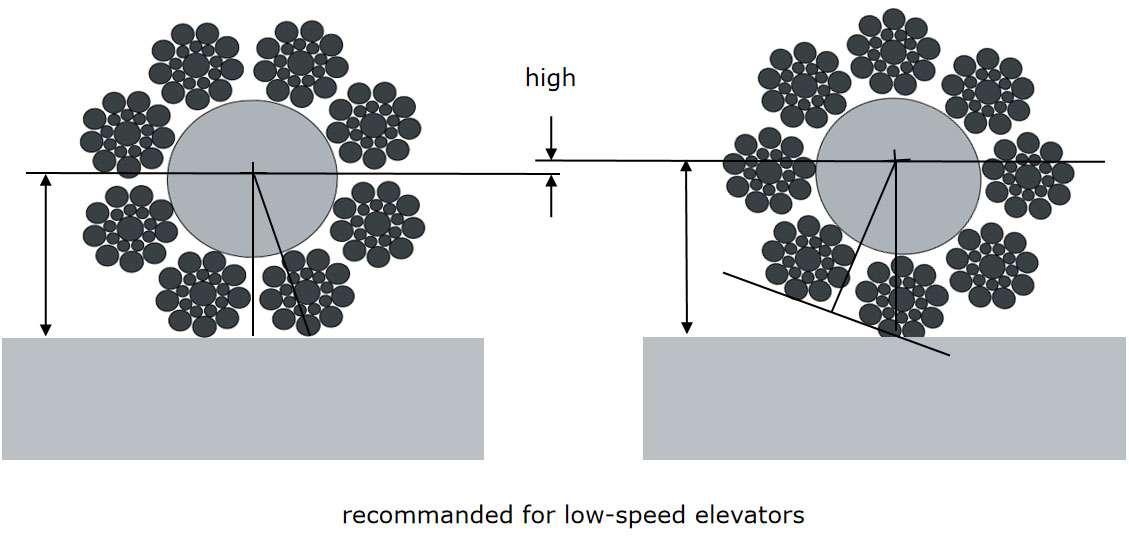

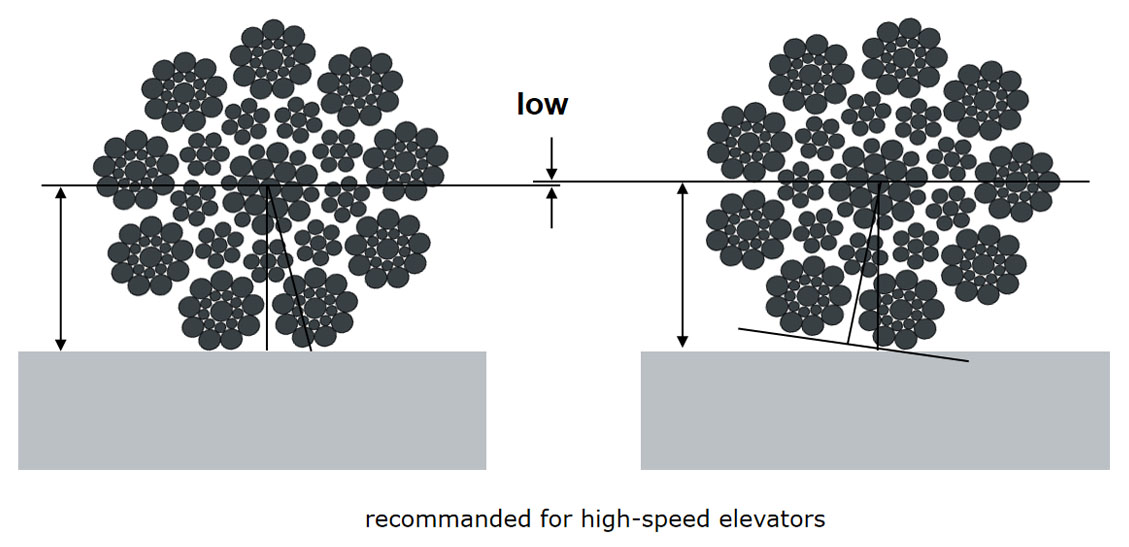

Vibration of ropes with 8 strands

Vibration of ropes with 9 strands

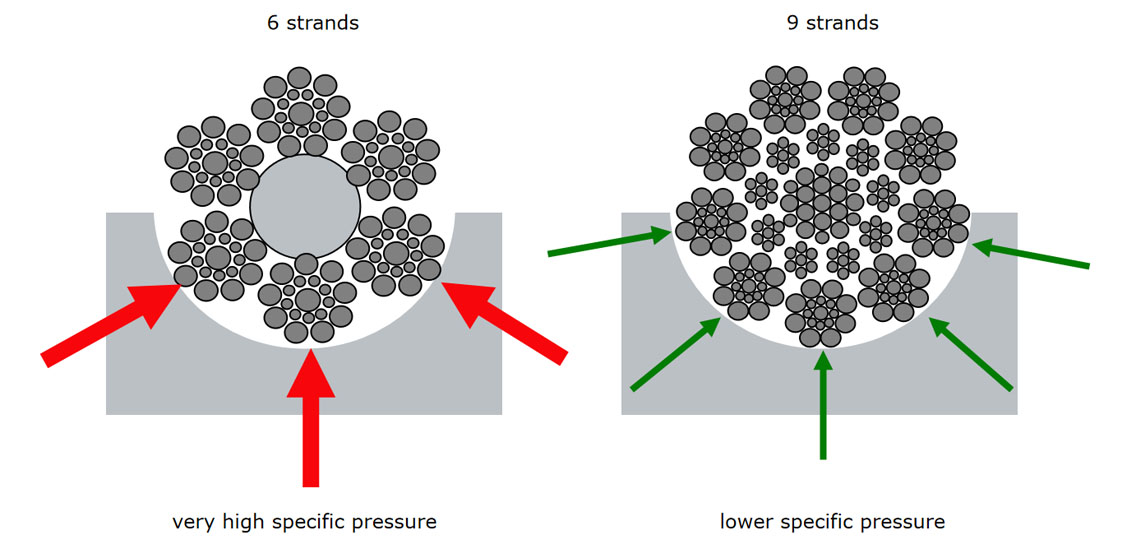

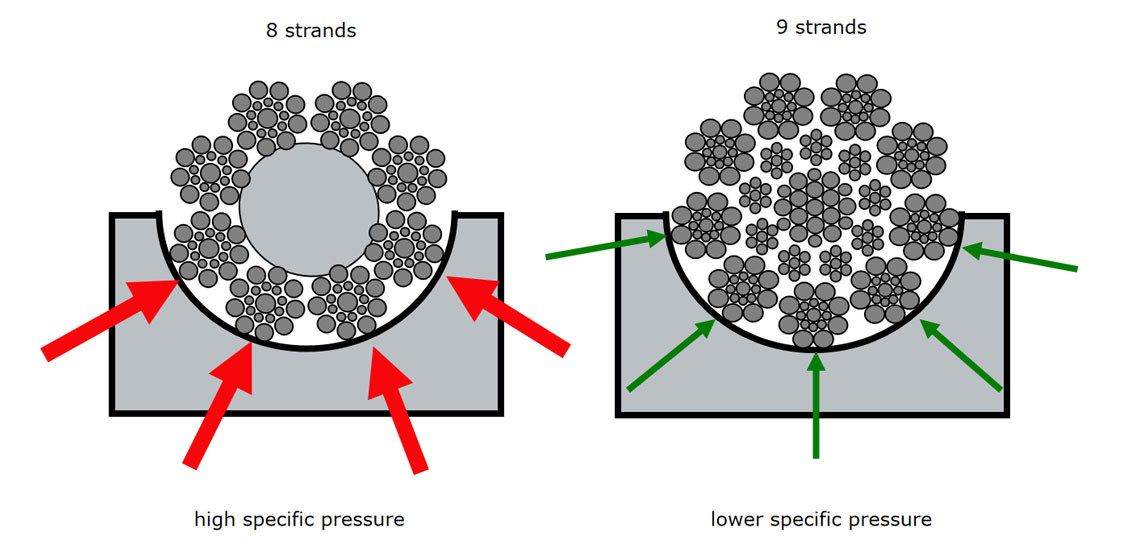

Groove pressure of elevator ropes

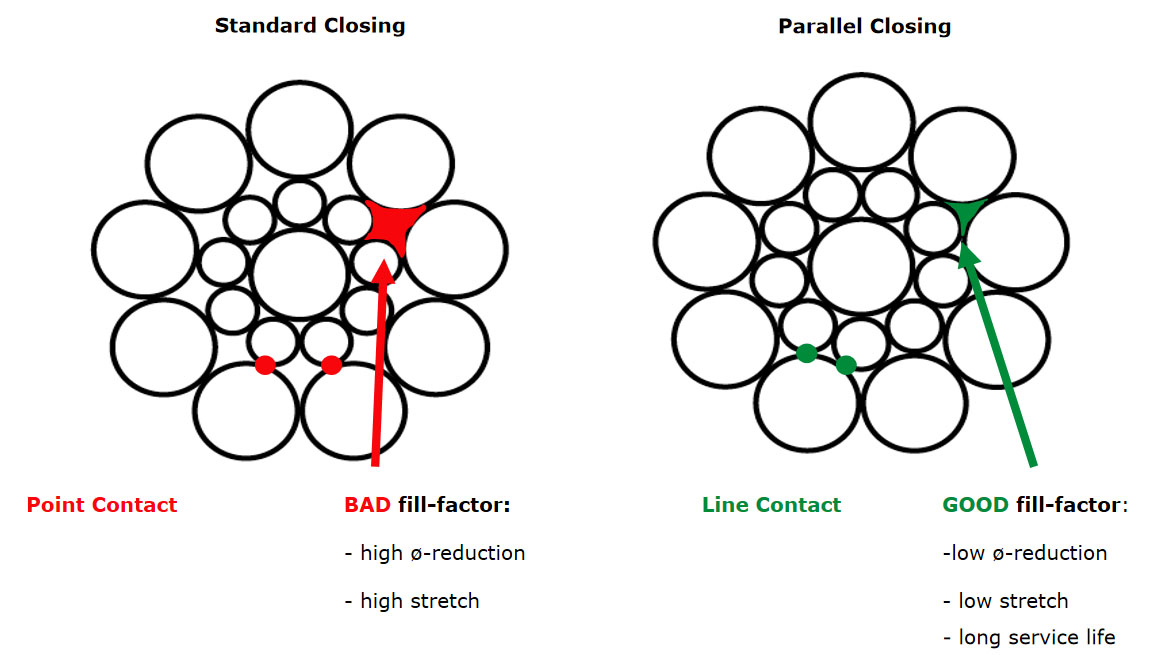

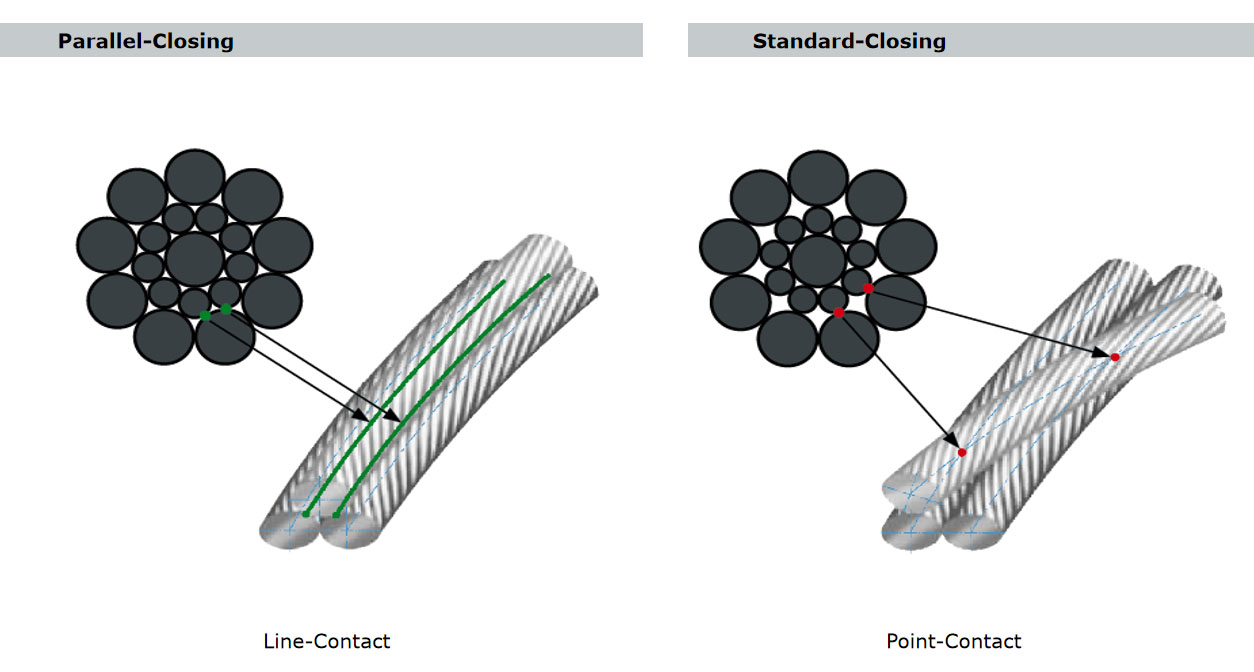

Standard / Parallel Closing

HRS

• high flexibility

• very high breaking load

• optimal load distribution due to line contact between the strands

• minimum rope diameter reduction during service

• minimum elastic elongation

• minimum lasting elongation

• long application period • high travel comfort

Post time: Feb-24-2022