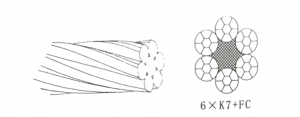

During stranding,the strands of compacted steel wire rope after compaction processing such as die drawing, rolling or forging , the diameter of strands become smaller , the surface of stands become smoother, and the contact surface between the steel wires increases. The steel wires in the strands contact each other with a helical surface, which are formed on the basis of a linear contact structure. as shown in the picture.

Typical structure of compacted steel wire rope:

6*K7+FC(IWS), 6*K9S+FC(IWR), 6*K25Fi+FC(IWR), 6*K26WS+FC(IWR), 6*K29Fi+FC(IWR), 6*K32WS+FC(IWR), 6*K36WS+FC(IWR), 35W*K7 and so on.

Features of compacted steel wire rope

1. The strands of Compacted steel wire rope after compaction processing, the steel wires in the strands are no longer circular sections, and the steel wires contact each other with a helical surface.

2.The metal filling coefficient in the compacted steel wire rope is large (generally above 0.9), and the gap between the steel wires is very small.

3.The surface of the strand circumference of the compacted steel wire rope becomes smooth

4.The structure of compacted steel wire rope strands is stable and elongation is small.

5.Compared with the ordinary round steel wire rope, the compacted steel wire rope has a higher breaking force, and a larger contact area with the pulley or drum, which makes the compacted steel wire rope more wear and corrosion resistance. When using the ropes on multi-layer coiled drums, the smooth surface of the compacted steel wire rope ensures that adjacent ropes will not be scratched or damaged due to friction. This feature makes the compacted steel wire rope more suitable for multi-layer coiling.

6.When the compacted steel wire rope is under load, due to the large contact area between the steel wires, the contact stress between the steel wires is smaller than that of the linear contact steel wire rope.

Post time: May-17-2023