Products

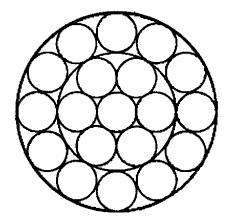

Manufacturing Companies For Braided Steel Wire Rope - Stainless Steel Wire Rope with SS316 and SS304 – Elevator

Manufacturing Companies For Braided Steel Wire Rope - Stainless Steel Wire Rope with SS316 and SS304 – Elevator Detail:

Product parameters

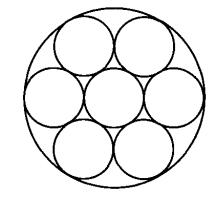

1-7

1-19

7-19

7-7

1-7

|

Construction |

|

||||

|

Nominal Diameter |

Approximate Weight |

Minimum Breaking Load Corresponding To Rope Grade Of |

|||

|

1570 |

1670 |

1770 |

1870 |

||

|

MM |

KG/100M |

KN |

KN |

KN |

KN |

|

0.5 |

0.125 |

- |

0.255 |

- |

- |

|

1 |

0.5 |

- |

1 |

- |

- |

|

1.5 |

1.125 |

1.9 |

2.02 |

2.15 |

2.27 |

|

2 |

2 |

3.63 |

3.87 |

4.11 |

4.35 |

|

2.5 |

3.125 |

4.88 |

5.19 |

5.5 |

5.81 |

|

3 |

4.5 |

7.63 |

8.11 |

8.6 |

9.08 |

|

4 |

8 |

12.8 |

13.7 |

14.5 |

15.3 |

|

5 |

12.5 |

19.5 |

20.7 |

22 |

23.2 |

|

6 |

18 |

30.5 |

32.4 |

34.4 |

36.3 |

|

7 |

24.5 |

43.9 |

46.7 |

49.5 |

52.3 |

|

8 |

32 |

51.5 |

54.8 |

58.1 |

61.4 |

|

9 |

40.5 |

68.6 |

73 |

77.4 |

81.7 |

|

10 |

50 |

93.4 |

99.4 |

105 |

111 |

|

11 |

60.5 |

112 |

119 |

126 |

1333 |

|

12 |

72 |

122 |

129 |

137 |

145 |

1-19

|

Construction |

|

||||

|

Nominal Diameter |

Approximate Weight |

Minimum Breaking Load Corresponding To Rope Grade Of |

|||

|

1570 |

1670 |

1770 |

1870 |

||

|

MM |

KG/100M |

KN |

KN |

KN |

KN |

|

1 |

0.51 |

0.83 |

0.88 |

0.93 |

0.99 |

|

1.5 |

1.14 |

1.87 |

1.99 |

2.11 |

2.22 |

|

2 |

2.03 |

3.32 |

3.54 |

3.75 |

3.96 |

|

2.5 |

3.17 |

5.2 |

5.53 |

5.86 |

6.19 |

|

3 |

4.56 |

7.48 |

7.96 |

8.44 |

8.91 |

|

4 |

8.12 |

13.3 |

14.1 |

15 |

15.8 |

|

5 |

12.68 |

20.8 |

22.1 |

23.4 |

24.7 |

|

6 |

18.26 |

29.9 |

31.8 |

33.7 |

35.6 |

|

7 |

24.85 |

40.7 |

43.3 |

45.9 |

48.5 |

|

8 |

32.45 |

53.2 |

56.6 |

60 |

63.4 |

|

9 |

41.07 |

67.4 |

71.6 |

75.9 |

80.2 |

|

10 |

50.71 |

83.2 |

88.5 |

93.8 |

99.1 |

|

11 |

61.36 |

100 |

107 |

113 |

119 |

|

12 |

73.02 |

119 |

127 |

135 |

142 |

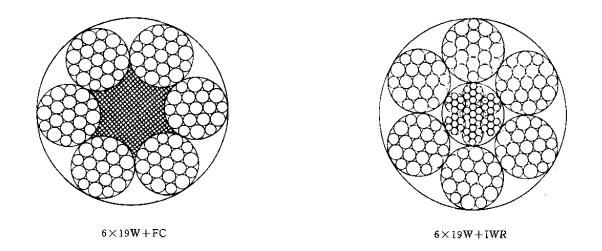

7-19

|

Construction |

||||||||||

|

Nominal Diameter |

Approximate Weight |

Minimum Breaking Load Corresponding To Rope Grade Of |

||||||||

|

Fiber Core |

Steel Core |

1570 |

1670 |

1770 |

1870 |

|||||

|

FC |

IWS |

FC |

IWS |

FC |

IWS |

FC |

IWS |

FC |

IWS |

|

|

MM |

KG/100M |

KN |

|

|

|

|

|

|

|

|

|

1.5 |

0.83 |

0.81 |

1.12 |

1.31 |

1.19 |

1.39 |

1.26 |

1.47 |

1.33 |

1.56 |

|

2 |

1.48 |

1.44 |

1.99 |

2.33 |

2.12 |

2.47 |

2.25 |

2.62 |

2.38 |

2.77 |

|

2.5 |

2.31 |

2.25 |

3.12 |

3.64 |

3.32 |

3.87 |

3.51 |

4.1 |

3.71 |

4.33 |

|

3 |

3.32 |

3.24 |

4.49 |

5.24 |

4.78 |

5.57 |

5.06 |

5.91 |

5.35 |

6.24 |

|

4 |

5.9 |

5.76 |

7.99 |

9.32 |

8.5 |

9.91 |

9.01 |

10.51 |

9.52 |

11.1 |

|

5 |

9.23 |

9 |

12.48 |

14.57 |

13.28 |

15.49 |

14.07 |

16.42 |

14.87 |

17.35 |

|

6 |

13.3 |

13 |

18.6 |

20.1 |

19.8 |

21.4 |

21 |

22.6 |

22.2 |

23.9 |

|

8 |

23.6 |

23 |

33.1 |

35.7 |

35.2 |

38 |

37.3 |

40.3 |

39.4 |

42.6 |

|

10 |

36.9 |

36 |

51.8 |

55.8 |

55.1 |

59.4 |

58.4 |

63 |

61.7 |

66.5 |

|

12 |

53.1 |

51.8 |

74.6 |

80.4 |

79.3 |

85.6 |

84.1 |

90.7 |

88.8 |

95.8 |

|

14 |

72.2 |

70.5 |

101 |

109 |

108 |

116 |

114 |

123 |

120 |

130 |

|

16 |

94.4 |

92.1 |

132 |

143 |

141 |

152 |

149 |

161 |

157 |

170 |

|

18 |

119 |

117 |

167 |

181 |

178 |

192 |

189 |

204 |

199 |

215 |

|

20 |

147 |

144 |

207 |

223 |

220 |

237 |

233 |

252 |

246 |

266 |

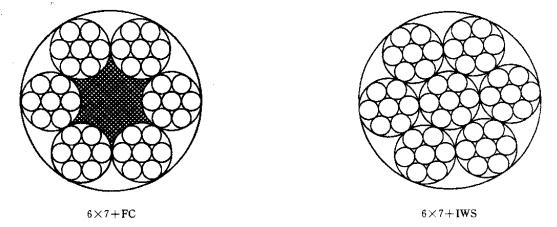

7-7

|

Construction |

||||||||||

|

Nominal Diameter |

Approximate Weight |

Minimum Breaking Load Corresponding To Rope Grade Of |

||||||||

|

Fiber Core |

Steel Core |

1570 |

1670 |

1770 |

1870 |

|||||

|

FC |

IWS |

FC |

IWS |

FC |

IWS |

FC |

IWS |

FC |

IWS |

|

|

MM |

KG/100M |

KN |

||||||||

|

0.5 |

0.092 |

0.09 |

0.127 |

0.149 |

0.135 |

0.158 |

0.144 |

0.168 |

0.152 |

0.177 |

|

1 |

0.367 |

0.36 |

0.511 |

0.596 |

0.543 |

0.634 |

0.576 |

0.672 |

0.608 |

0.71 |

|

1.5 |

0.826 |

0.81 |

1.15 |

1.34 |

1.22 |

1.42 |

1.29 |

1.51 |

1.37 |

1.59 |

|

2 |

1.47 |

1.44 |

2.08 |

2.25 |

2.21 |

2.39 |

2.35 |

2.54 |

2.48 |

2.68 |

|

3 |

3.3 |

3.24 |

4.69 |

5.07 |

4.98 |

5.39 |

5.28 |

5.71 |

5.58 |

6.04 |

|

4 |

5.88 |

5.76 |

8.33 |

9.01 |

8.87 |

9.59 |

9.4 |

10.1 |

9.93 |

10.7 |

|

5 |

9.18 |

9 |

13 |

14 |

13.8 |

14.9 |

14.6 |

15.8 |

15.5 |

16.7 |

|

6 |

13.22 |

12.96 |

18.7 |

20.2 |

19.9 |

21.5 |

21.1 |

22.8 |

22.3 |

24.1 |

|

8 |

23.5 |

23.04 |

33.3 |

36 |

35.4 |

38.3 |

37.6 |

40.6 |

39.7 |

42.9 |

|

10 |

36.72 |

36 |

52.1 |

56.3 |

55.4 |

59.9 |

58.7 |

63.5 |

62 |

67.1 |

|

12 |

52.88 |

51.84 |

75 |

81.1 |

79.8 |

86.3 |

84.6 |

91.5 |

89.4 |

96.6 |

Six points for attention in the use of stainless steel wire rope

1.Don’t use the new stainless steel wire rope directly at high speed and heavy load

The new stainless steel rope should not be used directly at high speed and heavy load, but run for a period of time under low speed and medium load conditions. After the new rope is adapted to the state of use, then gradually increase the running speed of the wire rope and the lifting load.

2.The stainless steel rope can not disengaged from the groove

When the stainless steel wire rope is used with the pulley, please take attention that the ropes care can not disengaged from the pulley groove . If the wire rope continues to use after falling off the pulley groove, the wire rope will be squeezed and deformed, kinked, broken, and broken strands, which will seriously shorten the service life of the wire rope. If the rope breaks, it will often bring grave consequences.

3.Don’t press the stainless steel wire rope

The stainless steel wire rope should not be strongly pressed to avoid deformation during use, or it will lead to wire breakage, strand breakage, or even rope breakage, which will shorten the service life of the wire rope and endangers operational safety.

4.Don’t rub with other objects when the stainless steel wire rope is running at high speed

When the stainless steel wire rope is running at high speed, the friction between the stainless steel rope and the objects outside the wheel groove is the main reason of early wire break.

5.Don’t wind the stainless steel wire rope randomly

When the stainless steel wire rope is wound on the drum, it should be arranged as neatly as possible. Or the steel wire rope will be damaged during operation.This will cause the wire breakage, which directly affects the service life of the steel wire rope.

6.Don’t overload the stainless steel wire rope

If the stainless steel wire rope is overloaded, it will rapidly increase the degree of squeeze deformation, and the degree of wear between the inner steel wire and the outer steel wire and the matching wheel groove will bring serious harm to the safety of operation and shorten the service life of the pulley.

Application

Product detail pictures:

Related Product Guide:

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Manufacturing Companies For Braided Steel Wire Rope - Stainless Steel Wire Rope with SS316 and SS304 – Elevator , The product will supply to all over the world, such as: Spain, Portland, Sydney, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!